The modern toilet design, while functional for areas with access to centralized sewage systems, is not suitable for many locations and is highly wasteful. The need for a better sanitation solution in the developing world and a less wasteful solution for the developed world is clear.

Sedron® has developed the Firelight® Toilet, a complete blackwater recycling system that achieves:

- 100% pathogen destruction

- Nutrient removal

- Recyclable flush water

- Phosphorus-rich, dry byproduct

- Modular design that allows system to be applicable in a variety of use cases

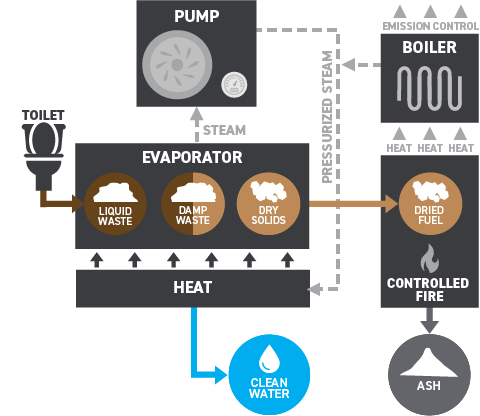

THE PROCESS

The Firelight® Toilet is based upon a proven, energy-efficient process known as mechanical vapor recompression. The waste is separated into solid and liquid fractions through thermal evaporation. The resulting vapor is then run through a pump to increase temperature and pressure. This pressurized vapor then becomes the heat source for the evaporation process, increasing efficiency by recapturing the energy of the most energy-intensive process in the cycle: phase change. In transferring its heat, the pressurized vapor condenses and forms a water output. The separated solids are metered into a controlled fire for further volume reduction and energy recovery within the system.

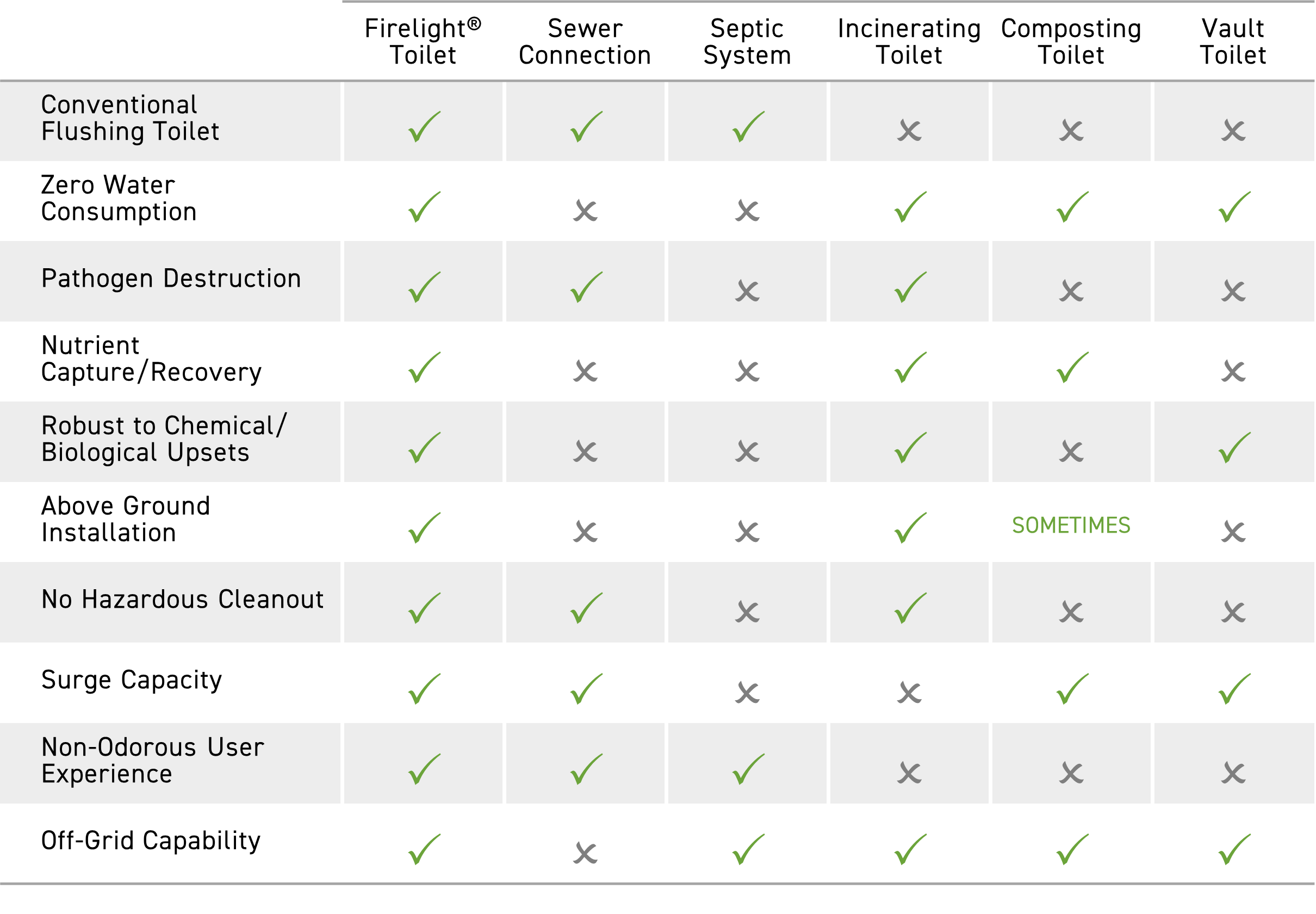

TOILET COMPARISON

FIRELIGHT® BENEFITS

COMPATIBLE WITH SEWER & SEPTIC SYSTEMS

The Firelight® Toilet eliminates the blackwater loading on traditional sewer and septic systems, and has the potential to replace the need for costly septic to sewer conversions in areas where uncontrolled nutrient loading is a concern.

PHOSPHORUS RECOVERY

100% of phosphorus is removed and concentrated through distillation into a manageable solid output. This significantly reduces nutrient loading on local ecosystems.

NITROGEN LOADING

All liquid effluent meets regulatory reclaimed flush water standards and can be disposed of without uncontrolled nitrogen loading on local ecosystems.

PATHOGEN-FREE BYPRODUCTS

The Firelight Toilet kills 100% of pathogens present in the blackwater waste stream.

WATER SAVINGS

The Firelight Toilet recycles flush water, benefitting both the environment and utility costs.

ROBUST SYSTEM

The system’s thermal and mechanical process is not susceptible to biological or chemical upset conditions requiring long process recovery times. No process chemicals required.

REAL ESTATE EFFICIENT

Compact footprint compared to competitive technologies such as septic and sewer, and less disruptive to install or maintain since the unit is entirely above ground.

COST SAVINGS

The Firelight Toilet provides the potential to replace traditional wastewater treatment processes including septage and sewer treatment plants, offering capital and operating cost savings.