Sedron® Technologies’ Varcor® system provides a highly efficient solution for processing liquid waste streams that concentrates and recovers the outputs into pathogen-free solid and liquid fractions. This approach to treatment is applicable to liquid waste streams such as:

> Wastewater biosolids

> Wastewater sidestream nutrient removal (both nitrogen and phosphorus)

> Dairy waste

> Low Carbon Fuel Standard (LCFS) digestate

> Raw septage

The Varcor can process any liquid waste stream with suspended or dissolved solids in it. Please reach out to Sedron to learn how The Varcor can help you handle your unique waste stream.

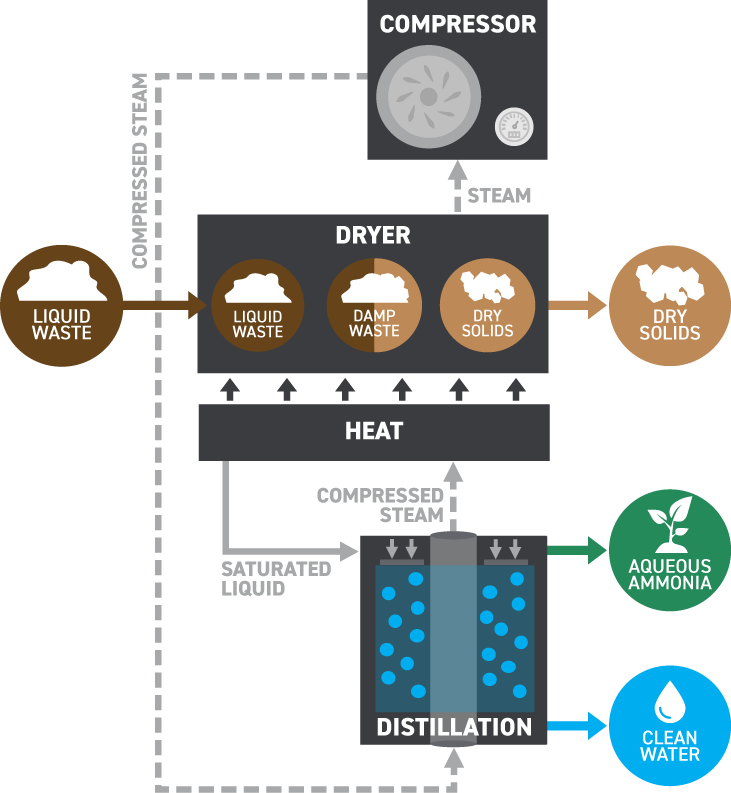

The Varcor technology is fundamentally based upon a well-proven process known as mechanical vapor recompression. The solid and liquid fractions are separated through thermal evaporation and the resulting vapor is sent to a compressor, where it undergoes mechanical recompression. The compressed vapor is then used as the heat source for the evaporation process. The low boiling point constituents (such as ammonia) are concentrated separately through a patented process.

Check out the Varcor operating on a Texas-based dairy farm in the video below.

DAIRY INDUSTRY

The Varcor® system is transformational to manure management on dairy farms. Using this technology, farmers can achieve compliance with environmental regulation while accruing significant cost savings as well as additional revenue streams. With Sedron Technologies’ Varcor system, manure will be efficiently distilled into:

1) Clean water for cows

2) Dry, sterile, and stable solids for use as bedding and/or soil amendments

3) Concentrated liquid, organic nitrogen fertilizer

This enables the farm to become a zero discharge dairy.

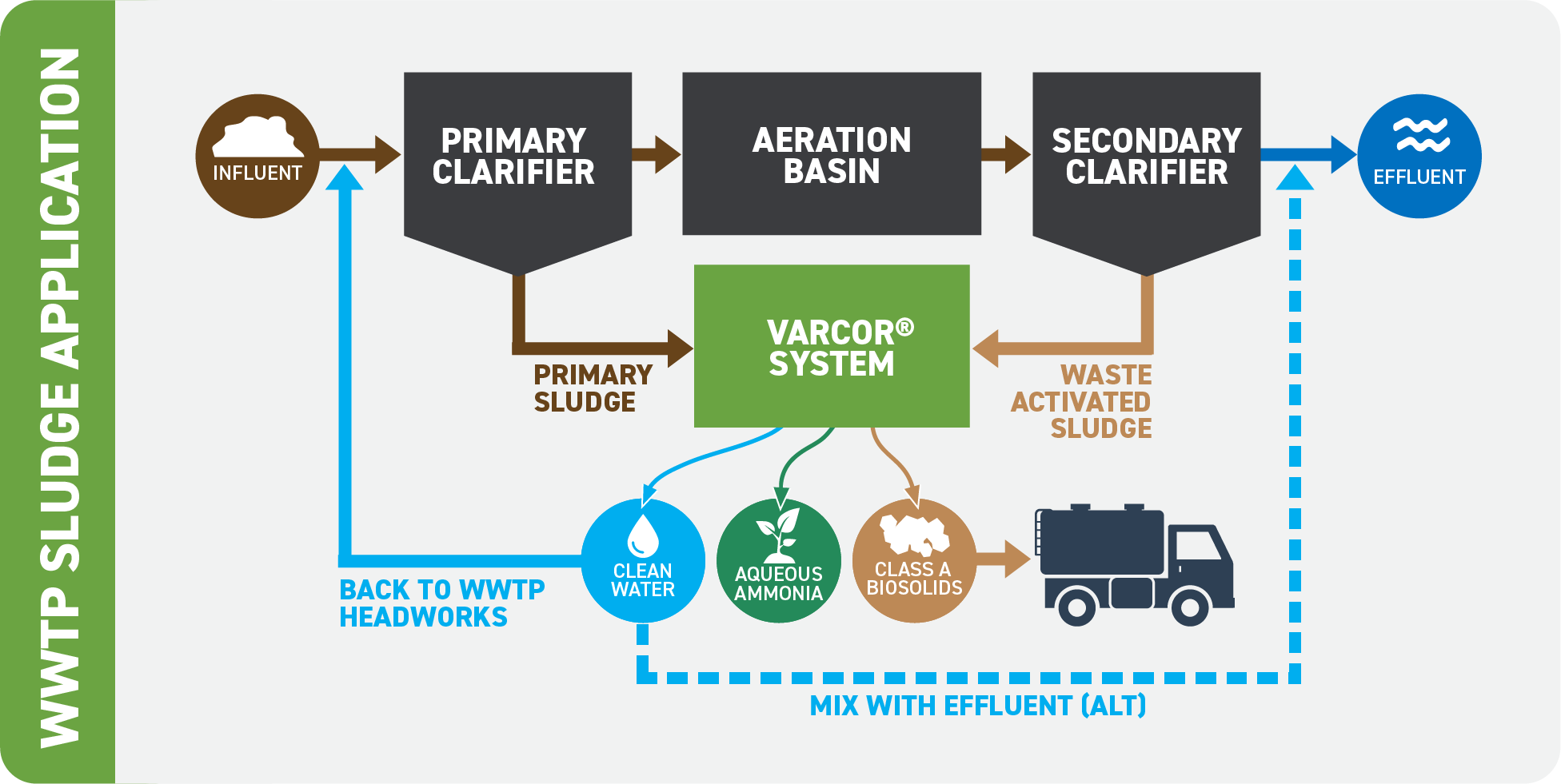

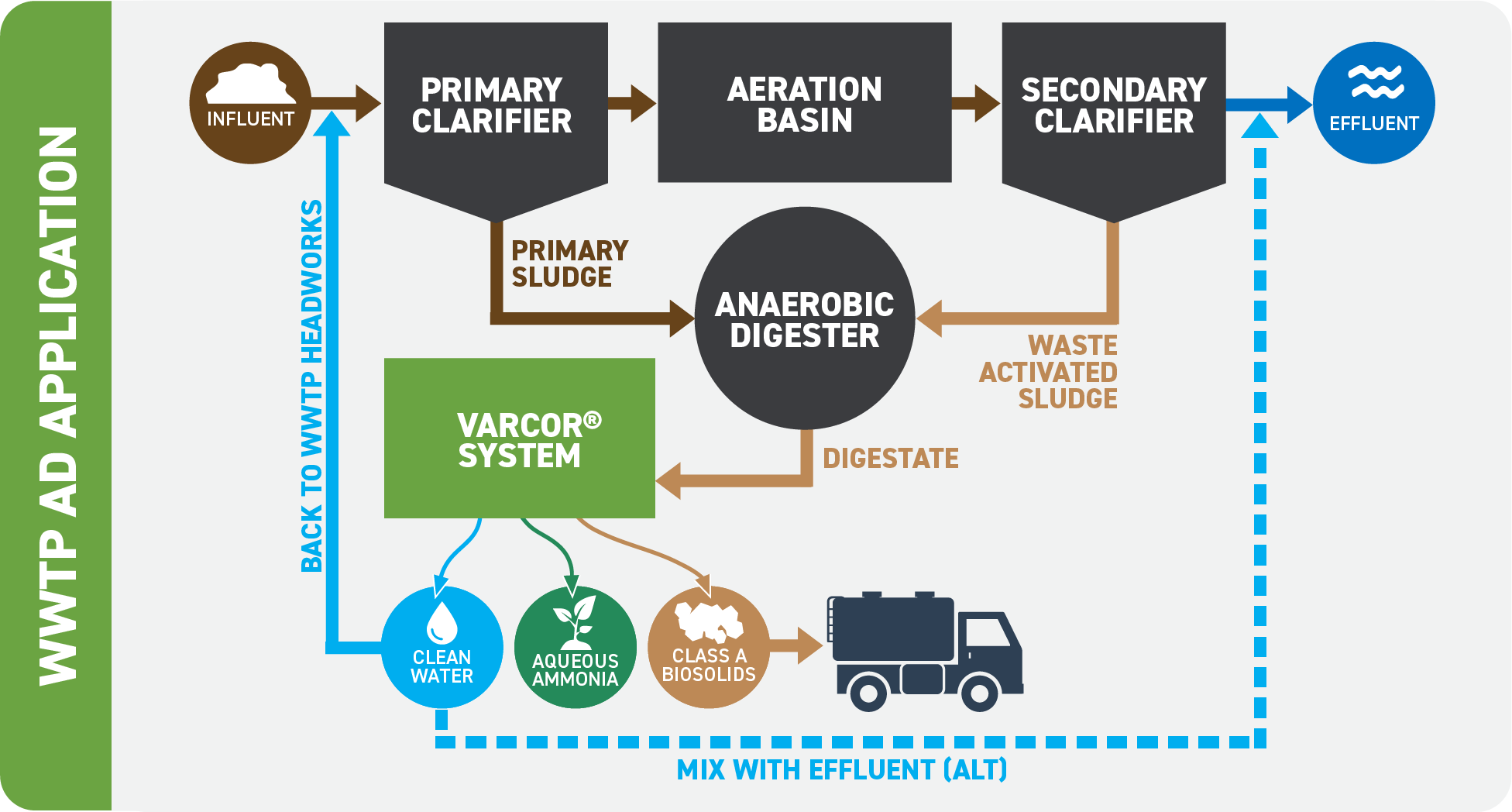

WASTEWATER TREATMENT PLANTS

In a wastewater treatment plant (WWTP) setting, the Varcor® is a complete, holistic solids handling and sidestream nutrient removal solution. the Varcor can completely replace or coexist with the following:

> Existing biosolids de-watering and drying systems

> Flocculants/Polymers

> Sidestream nutrient removal systems (including nitrogen and phosphorus)

> Digesters (if desired)

Two example installation options for the Varcor at a wastewater treatment plant: