FREQUENTLY ASKED QUESTIONS

Waste Processing

Desirable feedstocks for the Janicki Omni Processor include fecal sludge, wastewater treatment plant biosolids, pre-sorted municipal solid waste (MSW), and biomass fuel streams. Examples of acceptable MSW include paper and certain plastic products, domestic household waste, and biomass. The J-OP cannot process metal, glass, batteries, and several other toxic chemicals.

The J-OP is scalable and can serve populations ranging from community-scale to city-scale.

A household model has not yet been built, however, our engineers are working on developing a similar product: a self-sustaining household toilet that combusts waste as the fuel source. As this technology matures, we will provide more details about this product.

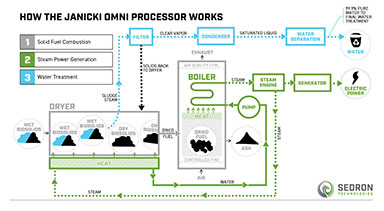

Depending on the type and moisture content of the waste streams, the preferred method is to combine any wet and dry material first before feeding or pumping into the dryer. If the waste stream is already dry, an auger mechanism would be used to feed the boiler directly.

This varies depending on the characteristics of the waste (e.g. heating value), but in general, the absolute minimum % solids content required for the J-OP's thermodynamic process to function is ~20%. At this solids content, no external energy source is required for drying. To optimize power production, ideally, the solids content would be closer to 50%. Wetter waste streams can be processed as long as auxiliary solid fuels (e.g. dry, biomass fuel) are also used to maintain the energy balance.

Water Treatment

This is dependent on the moisture content of the incoming waste and quantity of waste processed. The quantity will be dependent on the scale of the unit. As an example, the first commercial unit for Dakar can produce ~7,000 liters of clean water per day when processing 30 metric tons of fecal sludge at 50% solids.

The water treatment system integrated into the Janicki Omni Processor works by using a distillation process, multi-stage filtering in the vapor phase, condensing, followed by an additional multi-stage filtration process and aeration in the liquid phase. With the addition of the Water Purification Unit, ozone injection, micro- and ultra-filtration, activated carbon and pH correction are used to take the water to WHO and EPA potable drinking water standards.

Electricity

This is dependent on the waste stream/feedstock characteristics and scale of the unit for the application of interest. As an example, the first commercial unit for Dakar can produce 200-300 kW gross electricity continuously.

Yes, power production can be optimized by the unit's control system. With drier input streams, more electricity can be produced.

Yes, the J-OP is designed to operate independently of the electric grid. Note: The use of a diesel or natural gas- fueled electrical generator would be required during plant start-up.

Site Details / Operation

During start-up, the processor uses a diesel genset for electricity and auxiliary gaseous fuel (e.g. natural gas or butane) to kick-off the combustion process. Once the processor reaches steady-state, the processor becomes self-sustaining, at which time the auxiliary fuel source will turn off automatically and the electrical load can be picked up by the plant.

Our processors are designed to operate 24 hours/day, 7 days/week, and shut down only occasionally for periodic servicing or maintenance. Therefore, the consumption of auxiliary fuel and electricity from the grid should be minimal.

At a minimum, a reinforced concrete slab foundation, water drain, and utility connections/conduit are required. Additional requirements specific to the site may be necessary.

The Janicki Omni Processor is designed, engineered, and operated to ensure the exhaust or flue gas meets all applicable federal, state and local air quality requirements. The combination of a highly controlled thermal oxidation process in our fluidized sand bed and the downstream use of sorbent injection, particulate control via a cyclone and a filter baghouse, and other industry-standard control strategies are used to make this possible.

The J-OP is designed to minimize the release of odors. The waste vapor recovery process is under partial vacuum, thereby pulling air into the process, not forcing odors out. However, some odors may be present from other sources, i.e. the sludge or solid waste that is delivered to, or stored on, the site.

The J-OP footprint is dependent on the scale of the application. As an example, the first commercial unit in Dakar (which processed about 30 metric tons of fecal sludge per day) has an approximate footprint of ~21 m x ~27 m (~567 sq. m). The water purification unit, if included, fits in a standard shipping container and will take up an additional area of 12 x 2.5 meters. It is ideal to also have a minimum of 1,200 square meters to allow for trucks and other traffic to access the J-OP.

General Questions

The water output meets WHO standards for potable drinking water. The plant meets US EPA standards for emissions, and all of the engineering on the plant is fully compliant with ASME code standards.